SAP Business One Manufacturing

STEM Leverages SAP Business One with Custom Add-Ons Designed from Experience to Optimize Efficiency and Productivity in the Manufacturing Industry.

Common Challenges Faced by the Manufacturing Industry When Using SAP Business One Standard

The manufacturing industry using SAP Business One Standard often faces various operational challenges, particularly in managing complex and dynamic production processes. Companies frequently struggle with real-time monitoring of production processes, especially when ensuring product quality meets standards. Without adequate visibility, oversight and evaluation of production become limited, hindering efficiency and productivity. Additionally, companies experience difficulties in managing different versions of the Bill of Material (BOM) for a single item, impacting the accuracy of planning and material usage. Moreover, manually creating Production Orders is time-consuming and prone to errors, especially when they need to be customized to specific customer orders.

Bill of Material Mapping

Manage multiple version of Bill of Material of an item.

iShopfloor

Monitoring production process detail and

monitor the quality of production result.

Production Order Generator

Automate Production Order creation base on

an item or base on customer sales order.

Production Order Monitoring

Monitor production order status to help

manage production order more effectively.

The specialized add-ons developed by us at PT. Sterling Tulus Cemerlang (STEM) for SAP Business One provide solutions designed to address these challenges in Manfucaturing Industry. The iShopfloor module offers detailed production process monitoring capabilities, allowing better control over product quality, while the Production Order Monitoring feature helps track production status in real-time, providing insights for faster and more efficient decision-making. With the Bill of Material Mapping feature, companies can manage multiple BOM versions with greater flexibility. The Production Order Generator enables automation in creating Production Orders based on items or customer orders, saving time and reducing potential errors.

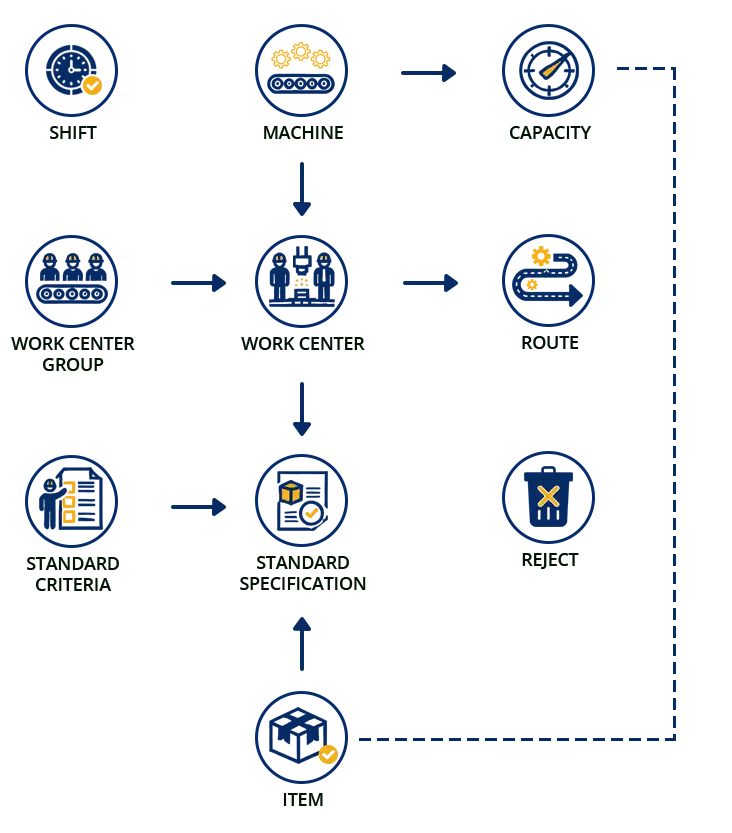

iShopfloor

Shop Floor & Quality Assurance

for SAP Business One

Manufacturing Clients